Magazine Articles Recreational Pilot New Zealand August 2000

We all have some special memories of particular moments in our flying experience, many of these being images no artist, let alone camera, could ever capture. On this trip, mine were of cloudscapes. Friday night, (the last scheduled SAAB flight to Timaru), layers of molten orange cloud with a strip of copper sky between, and dark islands of the Southern

Sunday, as I flew home, a variety of cloud forms and shapes inland and over the sea, left my book unread, and my neck sore (why-oh-why are the seats and the windows always out of line on airliners?). As the ATR approached

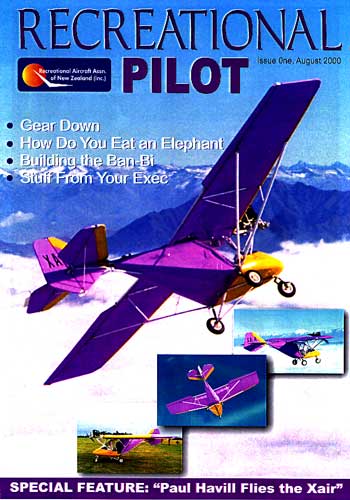

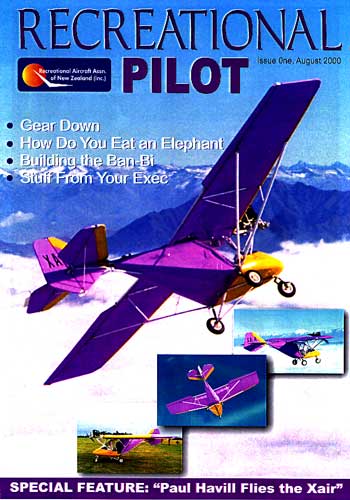

I was in Timaru to spend some time with Peter Stuy, the NZ agent for a new brand of Microlight, the X-Air, and get to know some of his and the X-Air's history. We enjoyed a marvelous day flying around Timaru, Ashburton and Waimate and I came away with a fund of great Australian flying yarns, and a very positive impression of the X-Air. Because of the nature of the weekend, this article is part travelogue as well as a flight review.

On Friday night, Peter met me at Timaru airport and within 10 minutes we were in his kitchen sitting down to a hot meal and getting to know each other. He has spent the last 31 years in

Once again I'd happened on a dream setup - wide open Southern skies, and a strip right on the back door. If we just strolled, it might have taken as much as 70 seconds to arrive at the hangar - I decided not to try a test sprint - 18 seconds looked possible, probably less if one of the geese had taken a dislike to me. Peter and his wife Zenaida live on a lifestyle block about a mile south of 02 at Timaru, in an old house, gradually being done up. He has built a hangar from the iron left over from re roofing, complete with trolley on rails, ramps and a mirror to check the lineup as he taxies in.

The X-Air is a very interesting plane. It is designed and manufactured in India, by a well established hang glider manufacturer, marketed through France, paid for in $US, with an Austrian engine, purchased through Australia with the NZ agency managed by an expatriate Dutchman! It would be hard to find a more international mix in any other product we use. It might sound like a fearsome combination, but the system works quite well, with deliveries in the 1 to 2 week bracket. Peters X-Air was 11 days from order to arrival, complete with apologies from

From the outset, it is obvious that the X-Air is the same general configuration as a Bantam, and while it is inevitable that comparisons be made, the purpose of this review is not to fly off one against the other, but to introduce the X-Air to NZ pilots. Each machine has its strong points, and if you do intend to shell out the dollars, then I suggest you fly both and make up your own mind, based on your own particular needs.

The X-Air has some distinctive features that draw your attention right away. First the apparently short fuselage boom, and its narrow neck just ahead of the tail. This is more an illusion than real, and stems from the combination of a sharp taper in the cabin streamlining, and the side profile of the cruciform tail. At the same location are a cluster of pulleys, about 4" in diameter, which, upon inspection, turn the aileron cables forward to the trailing edge, and the rudder cables aft.

The next noticeable feature is the undercarriage, a robust triangulated affair complete with compression springs and hydraulic dampers on all 3 wheels. This later proved able to withstand a considerable hammering that might cause owners of Challengers, Bantams, MX etc, to stop and carefully check before committing to flight and a subsequent landing.

The wing is noticeable for it's planform - swept LE and straight TE, like the Weed Hopper of the early 80s, and the single surface inboard TE, which acts rather like a fixed flap. The leading edge is a single smooth curve, with no sign of lumps of rib. I assumed that a sheet metal wrap had been decided on by the designer, but like the

The next item of interest is the cockpit. First of all, it's enclosed - really nice in the

The initial impression then, is of a familiar type, with a few different methods of achieving the same outcomes. It looks (and is) rather similar to a Bantam to fly, and at a pinch, anyone competent in a B22 could get in and fly the X-Air without too much effort. Regular readers will know of my liking for doing a type conversion, and certainly it helps with the X-Air, but is not essential.

Getting in is straightforward, the seat being at a reasonable height due to the undercarriage design, raising the cockpit somewhat higher than a Bantam. The standard squeeze around the struts is still there, as is the need to draw your feet in tight as for the large screen Challengers, but when seated; you don't need to decide whether to reach around the strut, or squish inboard - there is plenty of room. The 4 point belts are straight forward, but adjustment of the lower end is a bit of a fiddle the first few times, as is closing the somewhat floppy door. Initially this put me off somewhat, but having flown around, and got in and out half a dozen times, it was no longer a problem, although remained noticeable.

The design of the cockpit enclosure is satisfactory, and shows a simple approach to the problems of dealing with complex molding issues in an apparently low-tech country such as India (India has a very well developed aircraft industry, ranging from gliders to jet fighters). The main fiberglass pod is a straightforward chopped strand matt molding. The transparent bit is a cunning way of dealing with the need to develop a curved screen and matching doors. The screen and doors are made of Lexan sheet about 2mm thick and curved to fit around the main tubes, attached by a series of nylon tie wraps. The screen is made in two halves that meet up the middle, aligned with the centre support tube to the engine mount, and the compound curve effect is achieved by the double bend in the side tubes. The top hinged doors have two half frames, not joined in the middle, to allow the door to flex, aiding entry and exit. The top of each door is held to the centre strip by 3 simple fasteners, which allow it to be removed in 5 minutes for warm weather flying. There are no hinges, the lexan just flexes.

All this results in a rather floppy door, albeit with a support strut to hold it open, and some fiddling to shut it and latch it properly prior to flight. A pin several inches up from the bottom must be located in the corresponding hole, and then a bungee hook engaged, right by the lower outboard hip of the crewmember. It works well enough, but for regular club use, might need to be simplified so a variety of people can operate it reliably and quickly.

This turned out to be the only niggle in the whole operation, and would be easily remedied in one of several inventive Kiwi ways. The panel is straightforward, with the inclusion, in Peter's X-Air of GPS and a Navaid fuel flow meter. The fuel line makes a detour up the panel, via a sight glass, so there is direct indication of fuel, and a visual check for any crud or water in the system. The controls are really the most noticeable, especially the sticks - tall white enameled, and with a tapered wood grip that could only be described as "Designer French" in style. They have a wide range of movement, are positively interlinked, and accompanied by almost equally tall throttle levers, which have the biggest range of movement I have encountered in a Microlight (or possibly any other aircraft). The port one gets in the road while entering that side and is usually pushed forward to ease entry.

Again I was left to ponder the wonders of different design rationales, but rapidly grew to like the fine control afforded as well as realise that a 2cm accidental movement in bumpy conditions only results in a small rev change, not a sudden burst or otherwise of power. It will also help a student make a positive correlation between the throttle position, movement and response.

The bottom hinged and staggered rudder pedals are comfortably located, brakes on the left side only, but rather stiff in operation on the ground, due to the short connection moment to the nose gear.

There is a small (optional) zippered luggage compartment between and behind the seats, enough for an overnight bag and a small amount of camping gear if you are so inclined. The two fiberglass fuel tanks sit behind the seats, suspended from the surrounding frame by stainless straps and cable, and are filled from the right side after lifting a velcroed flap aft of the door.

Peter's X-Air is fitted with a Rotax 618 RAVE engine, and this supplied another item of interest. The engine itself is - well - typical Rotax, but has an automatically adjusting exhaust tuning valve with manual over-ride that can be adjusted to improve the running of the engine when set at a particular speed band. Once the engine had been primed (the choke control is rarely used) it fires up after about 3 or 4 prop tips and takes a few minutes to warm up. The RAVE can be adjusted to smooth the engine, and when it does so, there is a noticeable increase in RPM. (A smooth engine doesn’t waste energy shaking - it delivers it to the prop). This occurs because with any kind of tuned exhaust system, the area of the exhaust port controls how rapidly the hot gases leave the cylinder, and so how the pipe needs to be set up. There have been some experiments with adjustable length pipes, but the market seems to have settled on the RAVE technology as a practical solution, and it has been part of the motorcycle scene for a number of years.

Taxi holds no surprises, except for the way bumps are soaked up by the suspension. Peter is no slouch in this regard as a salesman, and we drove around enjoying the bumps on the way to line up for takeoff and probably looking like D.I.C. of a Microlight to any uninformed observer. We called lining up and rolling, and full throttle, followed by a touch on the RAVE, produced more than sufficient power, and we were off and climbing in about 6-7 seconds.

The X-Air impressed immediately with its rapid transition from ground to air, and an immediate solid feel in climb out and turn. I had expected the large wing area to result in a the odd wallow or heave, but none was present. We climbed through to 1500 and went for a little tiki tour prior to joining downwind for Timaru.

In the circuit, visibility is good, and the wing design allows a steep angle of descent, nose well down, without too much speed increase - great for short field work. Elevator authority is very positive, so round out can be achieved down to 35 knots indicated, without significant degradation. Later in the day, I found the same was true of glide (engine switched off) approaches. At much above 40 knots, some float occurs, and over 50 knots, this could be rather embarrassing (don't ask!).

This then was my first 10 minutes in the X-Air. Several surprises and a nice plane to fly. The next task was to organize the photo shoot, and Ian Sinclair had kindly volunteered the Coyote (RNS) for the task. What a shame - I'd have to fly in another interesting machine for a while to take photos. RNS has a 912 fitted, and is no slouch, but in the calm morning air the X-Air (1 POB) out climbed RNS (2 POB) no trouble at all, reaching the photo shoot altitude about a minute ahead of us, and at a much steeper climb angle. I wasn’t concerned, as Ian had turned the controls over to me so I was enjoying the bonus fly! We set up at about 4500 and proceeded to beetle around looking for sun angles, nice banked turns and the like, Ian flying and calling the shots to Peter in the X-Air, and me trying to take them and at the same time dodge the various tubes in RNS cockpit. Soon I had shot 2 rolls of film, and we headed back, Ian once again letting my twitching hands on the controls, all the way back to the hangar. He didn't even mention the extra touchdown I made (RNS is a tail dragger) - Thanks Ian. We had actually taken about 90 min to do the shoot, and after a wander around the facilities, and a chat, Peter and I headed back to his place for a coffee, then off to Ashburton to attend the Tee hangar syndicate opening. A great effort by the syndicate members has a large multi hangar for members use, and aircraft from around the district flew in for the opening and delicious BBQ laid on afterward.

The flight to Ashburton was picturesque at least for me - I hadn’t done it before, and illustrated the GPS effectively in three ways. It was great to have a little black box that thought (and did) know where it was all the time. No brain, just follow the arrow, secure in the knowledge that Peter knew where we were anyway.

In the absence of Peter and if the GPS fell over for any reason, I'd be lost instantly and would need a real paper map. Its all flat down there and my South Island geography knowledge is not as good as that of the

Morals - figure them out yourself ! Back to Ashburton. After the official bit and food, Peter and I wandered over to the hangars, and found much activity in one that turned out to be own by the local aviation museum. I had no idea there even was one, and could have spent hours in the restoration hangar, with a Vampire starting to look good, a Bergfalke glider partly restored, and other candidates such as a T31 and several basket cases, including the inevitable Tiger Moth fuselage. The members working on the Vampire were obviously enjoying themselves hugely, proud of their achievements, and willing to chat despite the interruptions. Next-door is the display hangar, with a Cropmaster, Venom, Merlin, Aeronca(?) Bofors (just in case), Agtruck and several others, along with the memorabilia and models typical of all museums. In all an excellent setup and credit to all concerned. If you are near Ashburton, make the effort to call in and enjoy the work that has been done. The box near the door is a great place to leave your donation and support the work.

Having chatted with a few friends, the Belworthys, Ashley's Johnson's Jabiru and spent a pleasant 40 min with Ken Carhill and his Challenger rebuild, it was time to fire up and head back to do some thinking flying. About 38 min found us on Peters home strip, at which point, he said to me & off you go for the afternoon and enjoy yourself.... what a gentleman...I decided to head down to Waimate to see the in-laws, and after a really short T/O, was airborne, IFR (SH1) and having a ball playing with the X-Air. The X-Air has a distinct step in attitude at cruise rpm, sitting slightly nose down, at 60 knots indicated, with 5900rpm and about 16 lit/hr showing on the Navaid fuel monitor. I tried to find some bumpy bits, but nothing challenging arrived, although I found a slight snaking occurred from time to time. A touch on either rudder pedal stopped it, and soon became a background action. Like many of us, I've played the hand and elbow game with Quicksilver's, Bantams, Pulsars etc and the twin sticks are great.

The long control column is very effective in that the amount of stick movement is significant even for what would be slight pressures in a short stick machine. This means the student gets a tangible comparison of the effects of slight moderate and large & deflections, without having to mentally transition between stick pressures for small control effects and stick movement for greater control effects and I can see the advantage this would give during instruction. This stick response deserved further exploration, and so I tootled along at various speeds to investigate. What I found was a superb correlation between the airspeed and the stick movement needed to gain a positive reaction from the airframe.

At low speeds - 30 knots - the stick can be really stirred in all directions, about 20cm/10” in roll or pitch, and a sluggish but definite response is there. As the speed increases (I went up in 5 knot increments), so the required stick movement decreases in direct proportion, so that at 50 knots only about 1/2 the movement is required, and a 60, rolls are entered and crisply and a push of about 5cm is enough to make you light in the seat. During this exercise, the ASI had an excellent response, with little lag evident in either pitch direction.

As I got up to 70 knots, there was a tendency for the nose to stay pointed down, and a slight push on the stick resulted in the X-Air quickly steepening the dive, reaching VNE in less than 10 seconds. The effect is easy to see, and just as easy to check. Initially I thought the CG was too far aft, as dynamic pitch instability is often a sign of this. A few more pokes and prods confirmed the effect really only became noticeable over 70 knots. Only one thing to do - check the stall. A sudden stall with possible stick pressure reversal would confirm the aft CG. Power off, nose up and slower and slower, down to 30, ridiculously nose high, wallowing about, some shudder and a gentle break at 28 indicated. No bite!? I’ll have another go - same again. Right - this time a slow (1kt/sec) deceleration in level flight and again the same. After a variety of stalls at various power settings and decelerations/attitudes, all I had achieved was to confirm excellent handling, a clean but manageable (for a student) break, and that mushing was also possible. Had I been mistaken about the 70 knots plus tuck? No, it’s was still there. There answer was supplied by Peter after I got back. He had been experimenting with a bungee in the elevator circuit, and the combination of it, and the trailing edge trim tab gave a divergent effect over 70. What happens is that the bungee relieves the trim tab of load at cruise, so it trails straight out, but for higher speeds, the tab must stretch the bungee, and so needs a greater angle of deflection. Because the force this produced increases with the square of the speed, it overpowers the bungee above about 70 and causes the dive without the bungee, the effect is absent, and pitch stability is normal. I’ve mentioned this at length more for the concepts involved than anything else. It certainly is a non-issue in terms of handling or stability, both of which are excellent. Roll was next to try so I started with a series of roll reversals, stopping on a landmark, and performed at 5-knot increments. At 30 knots, it was all rather wallowed but useable, with a few cm of rudder helping, until at 60, the response was quick and positive, still needing rudder and slightly more to the right than left. Adverse yaw is present and a sudden lateral stick movement results in the nose staying on track for nearly a second, while the wings roll to about 40 degrees, then there is a definite start to the actual turn at that point. Once in the turn, and properly co-coordinated there is little need for control input, although at about 70 deg sustained bank, some out aileron was needed, and a slight descent noticed.

Speed is stable throughout, and a good haul back on the pole produces an uncomfortable visual attitude, some shudder and so a good warning that it is time to ease off. Playing around with rudder produced no surprises, with a few seconds between input, yaw and a developing roll, which was just as easily checked and corrected with opposite rudder. This is probably due to the sweepback on the leading edge, which produces the same effect as dihedral, although for slightly different reasons. Rudder pressures are moderate and the control run free enough so that centering is good, with little residual yaw when the pedals are released.

Finally I played around with power, setting up for cruise at 45 knots, then adding full power, and 70 knots and reducing power. The aim was to look for a pitch-thrust interaction. There isn't a lot. In the former case, the nose remained at the same pitch attitude for a couple of seconds before the speed increase resulted in the expected climb, and in the latter case, just a gradual lowering of pitch to the descent appropriate to that trim.

When I stopped over at the Waimate strip, I'd wanted some approach photos, and so had the camera ready to go. The X-Air gives such a rock steady approach, and steering with the rudder is sufficiently effective, that I had no trouble banging off a few pix, not touching the stick or throttle at all form the start of base leg, leaving the plane to fly itself right down to the ground, (in case you are wondering, my hand was close to the stick and brain fully engaged from short finals) with just a trickle of power at 1-2 m to check the descent. Bit of a bump on arrival, but OK, so off I went for another try. This time I flew the whole circuit with just rudder and throttle, and while it wasn't as tidy a circuit as ideal, it was certainly manageable. On the way back from Waimate to Timaru, I flew using either rudder/throttle with constant trim, or rudder/trim with constant throttle, an exercise on my personal what if Murphy strikes list, with ease. The fuel consumption dropped back to 8.2 liters per hour during this 45 knot cruise, compared to about 15 lit/hr, two up at 60, or 26 liters per hour, two up sustained climb at full power. Even one up, the thirst increases noticeably over about 65 knots, meaning 60 is a practical economical cruise. Obviously, a smaller engine (503-582) won't have quite the same thirst, but might still have a similar total consumption, as it would work a bit harder in cruise to produce the equivalent numbers.

Finally I arrived back at Timaru and having cunningly avoided the commercial flight of the day, was able to try some power off, and then engine off landings. This is the second major area in which the handling and performance of the X-Air shines. From 1200 feet overhead, I was able to switch off, try a stall, a steep 360 turn in both directions, then a short downwind, turn onto base at 250 feet, finals at 150 feet; then a slip across the main seal (20 02) onto 11, a bit fast, so some float, and a smooth touchdown. Start up and roll for another, this time no slip, but hold the nose up a bit for 35 knots and a firm sink rate, check forward slightly for 40 over the last few seconds, so I've enough to flare - another greaser - where the hell is an audience when you get it right? This is fun (4 more times!). Finally I had to head back to Peter's strip and give back the X-Air. I'd had a pile of fun, learned a lot more and been reminded that there is still more to learn and polish.

I'd like to have had some good thermals to work, as I believe the X-Air would tackle that task well, and the float option looks especially interesting..

The X-Air is a soundly designed and constructed machine, very well suited to the training role because of its control geometry and response, and robust undercarriage. The airframe 'talks' to the pilot well, and will help a student build experience and confidence readily. It has good cross-country potential with a full enclosure, excellent low speed handling and economical cruise. Visibility is good in most directions, the swept LE being helpful in clearing turns, and noise levels are tolerable for some hours at a time.